Why Polyurethane Foam Insulation Is Revolutionizing Modern Construction

Introduction

In today’s fast-paced world, efficiency and sustainability are at the forefront of building design and industrial manufacturing. Polyurethane foam insulation has emerged as one of the most reliable materials, offering unmatched thermal performance, structural support, and versatility. Its rigid form, known as Rigid polyurethane foam, is widely recognized as a go-to solution for applications where lightweight strength and energy efficiency are critical. This article explores the unique properties, applications, and advantages of polyurethane foams in modern industries.

What Makes Rigid Polyurethane Foam Special?

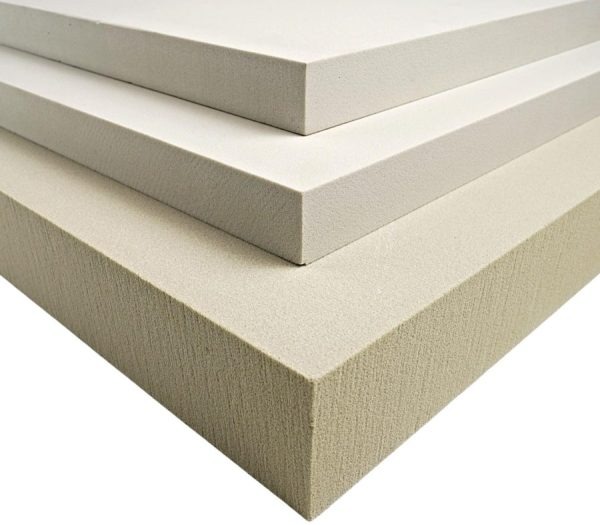

Rigid polyurethane foam stands apart from other insulation materials due to its combination of mechanical strength and thermal efficiency. Unlike flexible foams, rigid foams maintain their shape under stress, making them ideal for structural applications. They are also highly adaptable, capable of bonding to a variety of surfaces, which enhances their usability in construction and industrial projects.

The closed-cell structure of rigid polyurethane foam ensures excellent thermal insulation while providing resistance to moisture and chemical exposure. This makes it suitable not just for insulation, but as a core material in composite panels, furniture, and even transportation systems.

Expanding Commercial Applications

Polyurethane foams have evolved from their initial commercial use in the mid-20th century to become integral in numerous industries:

- Building and Construction: Rigid polyurethane foam is widely used in walls, roofs, and floors for residential and commercial projects. CE-marked foams ensure compliance with safety standards while offering superior thermal insulation. With densities ranging from 33 to 60 kg/m³, these foams deliver both efficiency and structural integrity.

- Refrigeration and Cold Storage: Thanks to their exceptionally low thermal conductivity (0.022–0.028 W/m·K), rigid foams are perfect for cold storage facilities, refrigerated trucks, and insulated panels. They maintain consistent temperatures, reducing energy consumption and protecting sensitive products.

- Automotive and Aerospace Applications: Lightweight yet sturdy, rigid foams are used in bus, coach, and aircraft panels. They provide structural support without adding excessive weight, contributing to fuel efficiency and overall performance.

- Furniture Manufacturing: Rigid polyurethane foam enhances the durability and comfort of furniture while serving as a cost-effective core material in composite construction.

Fire Safety and Phenolic Foam Performance

A significant advantage of modern foam insulation is its fire-resistant capabilities. Phenolic foams, a variant of rigid polyurethane foam, offer outstanding fire performance. Being thermoset materials, they do not melt or drip, ensuring safety in critical applications.

Phenolic foams meet strict international fire certifications:

- EN 13501-1 Euro Class B-s1-d0

- UK Class O / Low Risk

- French M1, Scandinavian NT 036 Class 1

- German B1, Dutch Class 1

These foams are capable of limiting fire propagation in ventilated façades and insulated wall systems, making them suitable for high-rise buildings. Their extremely low smoke and toxic gas emissions enhance safety in both commercial and residential environments.

Thermal Performance: Maximizing Energy Efficiency

The thermal performance of Polyurethane foam insulation is exceptional. The closed-cell structure traps gases within small, stable pockets, minimizing heat transfer. This allows for thinner panels without compromising insulation effectiveness, saving both space and materials.

Key thermal benefits include:

- Superior Resistance to Heat Transfer: Lambda values as low as 0.018 W/m·K.

- Long-Term Stability: Thermal properties remain consistent over time.

- Cost and Energy Savings: High efficiency reduces heating and cooling expenses.

- Reduced Material Thickness: Thin panels optimize interior space without compromising insulation quality.

By maintaining excellent insulation over decades, rigid polyurethane foams help buildings meet stringent energy efficiency regulations and contribute to long-term sustainability.

Strength and Structural Advantages

Rigid polyurethane foam is not just an insulator—it also provides structural reinforcement. Its high strength-to-weight ratio allows it to support significant loads, making it ideal for applications such as walk-on ceiling panels, composite construction cores, and ducting supports.

High-density foams (up to 200 kg/m³) can withstand static weights of over 225 tonnes per square meter, demonstrating remarkable mechanical resilience. Combined with resistance to moisture and mildew, rigid foams are exceptionally durable and long-lasting, even in challenging environments.

Moisture Resistance and Longevity

One of the key challenges in insulation is moisture infiltration. Rigid polyurethane and phenolic foams excel here due to their closed-cell design and non-wicking properties. Any moisture that enters is limited to localized areas, preventing water from spreading and compromising the material’s performance.

This makes these foams particularly useful in humid climates, refrigeration units, and coastal construction. Their resistance to chemical solvents, oils, and resins also ensures that the insulation remains intact under industrial conditions.

Environmental Impact and Sustainability

Sustainability is a growing concern in modern construction. Polyurethane foams, including phenolic variants, are available in CFC-free and HCFC-free formulations, reducing environmental impact. By improving building thermal efficiency, these foams also contribute to significant CO2 reductions.

Closed-cell foams maximize thermal performance while minimizing material use, striking a balance between energy efficiency, structural integrity, and ecological responsibility. For businesses and homeowners aiming to meet sustainability targets, rigid polyurethane foam offers a practical and effective solution.

Advantages at a Glance

The key benefits of Polyurethane foam insulation and Rigid polyurethane foam include:

- Outstanding Thermal Efficiency: Minimizes heat transfer for energy savings.

- Structural Strength: Supports heavy loads without adding unnecessary weight.

- Fire Resistance: Phenolic foams provide excellent fire safety with low smoke emission.

- Moisture and Chemical Resistance: Ensures long-term durability and protection.

- Versatility Across Industries: From buildings to vehicles and industrial equipment.

- Environmental Friendliness: Supports energy efficiency and CO2 reduction initiatives.

- Space Optimization: Thin panels deliver high insulation without sacrificing interior space.

Beyond Traditional Construction

While commonly used in building insulation, rigid polyurethane foams have applications beyond traditional construction:

- Cold Storage and Refrigeration: Maintains low temperatures efficiently.

- Automotive and Aerospace: Provides lightweight structural cores.

- Furniture: Adds durability and comfort to composite furniture pieces.

- Industrial Equipment: Suitable for pipe supports, ducting panels, and walk-on ceiling composites.

This adaptability underscores the material’s widespread utility, making Rigid polyurethane foam a vital component in both everyday products and specialized industrial systems.

Conclusion

Polyurethane foam insulation is more than just a material—it’s a technological solution for energy efficiency, safety, and structural performance. Its rigid form, Rigid polyurethane foam, offers a unique combination of thermal efficiency, mechanical strength, moisture resistance, and fire safety, making it indispensable across industries.

Whether for high-rise buildings, cold storage facilities, transport vehicles, or industrial equipment, polyurethane foams provide reliable performance that saves energy, enhances durability, and meets stringent safety and environmental standards. By incorporating Rigid polyurethane foam, businesses and homeowners can achieve cost savings, sustainable construction, and long-term structural integrity.